Tiantai company is a professional manufacturer of beer and beverage equipment, provide complete solutions and services for brewing projects. Founded in 2012 in Jinan, Shandong Province, we has a registered capital of 12 million RMB. Our production base in located in the Sino-European High-Tech Industrial Part, covering a total area of 380 acres, with 95 acres dedicated to brewing equipment. The facility includes 34,000 square meters of production space, 6,500 square meters of office space, and 4,200 square meters of living space.

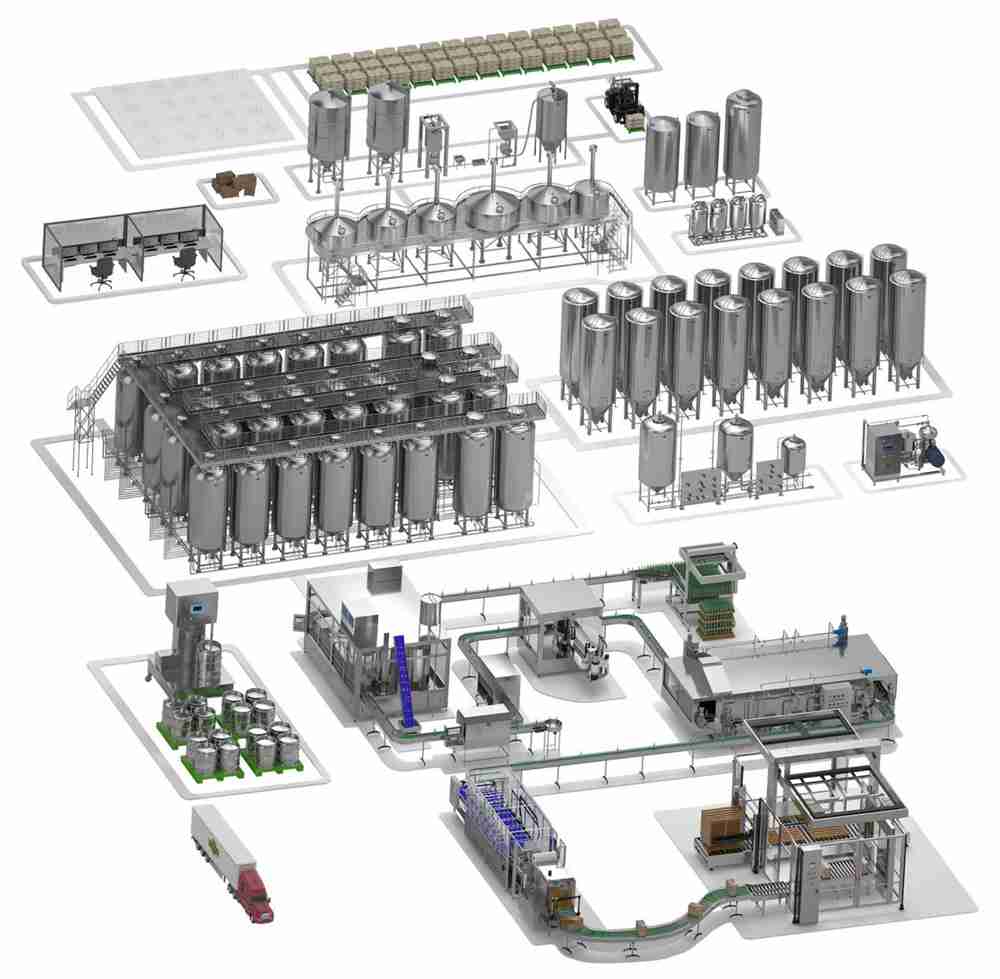

We specialize in high-quality brewing projects, offering end-to-end services from feasibility planning, engineering design, equipment manufacturing, project delivery, process development, to staff training. We provide turnkey solutions for beer brewing projects, including raw material handling, mashing systems, fermentation systems, yeast propagation, automated control systems, CIP cleaning, packaging systems, and utility support systems. Additionally, we produce high-quality equipment for fruit wine, distillation, rice wine, and bio-fermentation, making us a versatile supplier in the brewing industry.

Over the past decade, Tiantai has grown into a leading supplier of brewing equipment and a top engineering contractor in China. We’ve earned numerous honors, such as National High-Tech Enterprise, Specialized and Innovative SME, Most Innovative Enterprise, and Green Factory, etc.

I. Investment Plan

| Project Name | Content | Quantity | Estimated Investment |

| Procedures | Project Approval | 1 item | To be estimated by Party A |

| Land Approval | 1 item | To be estimated by Party A | |

| Planning and Design Approval | 1 item | To be estimated by Party A | |

| Environmental Assessment | 1 item | To be estimated by Party A | |

| Safety Assessment | 1 item | To be estimated by Party A | |

| SC Certification | 1 item | To be estimated by Party A | |

| Land Investment | Land Cost | 1 parcel | To be estimated by Party A |

| Land Preparation Cost | 1 item | To be estimated by Party A | |

| Tax Cost | 1 item | To be estimated by Party A | |

| Building Investment | Office Building | 1 building | To be estimated by Party A |

| Living Quarters | 1 building | To be estimated by Party A | |

| Production Plant | 1 unit | To be estimated by Party A | |

| Warehouse | 1 unit | To be estimated by Party A | |

| Infrastructure Investment | Power Supply Facilities | 1 set | To be estimated by Party A |

| Gas Supply Facilities | 1 set | To be estimated by Party A | |

| Water Supply Facilities | 1 set | To be estimated by Party A | |

| Environmental Protection Facilities | 1 set | To be estimated by Party A | |

| Transportation Facilities | Several | To be estimated by Party A | |

| Storage Facilities | Several | To be estimated by Party A | |

| Production Equipment Investment | Raw Material Processing Equipment | 1 set | See quotation |

| Brewing Equipment | 1 set | See quotation | |

| Filling Equipment | 1 set | See quotation | |

| Public Equipment Investment | Public Water Equipment | 1 set | See quotation |

| CIP Equipment | 1 set | See quotation | |

| Water Treatment Equipment | 1 set | See quotation | |

| Steam Supply Equipment | 1 set | See quotation | |

| Refrigeration Equipment | 1 set | See quotation | |

| Compressed Air Supply Equipment | 1 set | See quotation | |

| CO2 Supply Equipment | 1 set | See quotation | |

| CO2 Recovery Equipment | 1 set | See quotation | |

| Raw Material Investment | Malt | Several | See quotation |

| Hops | Several | See quotation | |

| Yeast | Several | See quotation | |

| CIP Chemicals | Several | See quotation | |

| Additives | Several | See quotation | |

| Personnel Investment | Brewing Workshop Staff | 5 people | See quotation |

| Packaging Workshop Staff | 15 people | See quotation | |

| Marketing Staff | 10 people | See quotation | |

| Management Staff | 5 people | See quotation |

II. Market Channel Plan:

| Channel Scenario | Recommended Packaging Forms |

| Large Supermarkets | Glass Bottles, Cans, Tinplate |

| Medium and Small Supermarkets | Glass Bottles, Cans, Tinplate |

| High-end Bars | KEG Barrels, Glass Bottles |

| High-end Restaurants | KEG Barrels, Glass Bottles |

| Ordinary Restaurants | KEG Barrels, Glass Bottles, Cans |

| Outdoor Restaurants | Insulated Barrels |

| Specialty Pubs | PET Barrels |

| Online | Glass Bottles, Cans, Tinplate |

| OEM (Original Equipment Manufacturing) | According to customer positioning |

III. Packaging Plan:

| Packaging Type | Draft (Tap) | Glass Bottle | Aluminum Can | Tin Can | Stainless Steel Keg | Insulated Keg | PET Keg |

| Specification | / |

330ml 500ml |

330ml 500ml 1L |

1L | 20L (US Standard) |

10L 5L |

20L 1.5L |

| Color | / |

Green Brown |

/ | / | / | / |

Brown Clear |

| Sealing Method | / |

Crown Cap Swivel Cap |

Pull Tab | Screw Cap | Type A Tap | Tap | Type A Tap |

| Labeling Method | / |

Three Labels Two Labels Single Label |

/ | / | / | / | / |

| Outer Packaging | / |

Cardboard Box Shrink Wrap |

Cardboard Box | Cardboard Box | / | / | / |

| Quantity per Outer Package | / | 12 bottles/box | 12 cans/box | 4 kegs/box | / | / | / |

IV. Beer Product Plan:

| Product | Wheat Beer | Lager | IPA | Stout | Pilsner | Fruit Beer |

| Beer Type | Ale | Lager | - | - | - | - |

| Wort Concentration | 12°P | 11°P | - | - | - | - |

| Alcohol Content | 4.1% ABV | 3.7% ABV | - | - | - | - |

| Malt |

Pale Barley Malt Wheat Malt |

Pale Barley Malt | Pale Barley Malt |

Pale Barley Malt Chocolate Malt |

- | - |

| Fermentation Cycle | 15 days | 28 days | 15 days | 15 days | - | - |

| Filtration Method | Centrifugal Filtration | Diatomaceous Earth Filtration | Centrifugal Filtration | None | - | - |

| Sterilization Method | - | - | None | None | - | - |

| Packaging | - | - | - | - | - | - |

V. Production Capacity Planning:

Total Production Capacity Planning| Total Capacity | Phase I Capacity Plan | Phase II Capacity Plan | |

| Planning Annual Capacity | 10000KL | 6000KL | 4000KL |

| Maximum Annual Capacity | 11550KL | ||

| Annual Brewing Days | 330 Days | 330 Days | 330 Days |

| Daily Average Capacity | ~30KL | ~20KL | ~10KL |

| Monthly Average Capacity | ~850KL | ~500KL | ~350KL |

Mashing Capacity Planning

| Total Capacity | Phase I | Phase II | |

| Work Shifts | 3 shits/24 hours | 2 shifts/16 hours | 3 shifts/24 hours |

| Mashing Batches | 6 batches | 4 batches | 6 batches |

| Mashing Batch Capacity | 5KL | 5KL | 5KL |

| Mashing Configuration | 5 Vessels | 5 Vessels | 5 Vessels |

| Mashing Capacity | 30 KL/Day | 20 KL/Day | 30 KL/Day |

Fermentation Capacity Planning:

| Total Capacity | Phase I | Phase II | |

| Average Fermentation Cycle | 20 Days | 20 Days | 20 Days |

| Minimum Total Fermentation Volume | >560 KL | >330 KL | |

| Fermentation Tank Specifications |

5KL*0 Tank 10KL*12 Tanks 20KL*12 Tanks 30KL*8 Tanks |

5KL*0 Tank 10KL*12 Tanks 20KL*12 Tanks |

30KL*8 Tanks |

| Actual Total Fermentation Volume | 600 KL | 360 KL | 240 KL |

Bright Beer Capacity Planning:

| Total Capacity | Phase I | Phase II | |

| Filtration Method | Diatomaceous Earth +Membrane Filtration | Diatomaceous Earth +Membrane Filtration | Diatomaceous Earth +Membrane Filtration |

| Filtration Time | 4-6 Hours | 4-6 Hours | 4-6 Hours |

| Filtration Capacity | 5 KL/Hour | 5 KL/Hour | 5 KL/Hour |

| Bright Beer Capacity |

10 KL*2 Tanks 20 KL*2 Tanks |

10 KL*2 Tanks 20 KL*2 Tanks |

30 KL*1 Tank |

Packaging Capacity Planning:

| Total Capacity | Phase I | Phase II | |

| Annual Packaging Capacity | 12000 KL | ||

| Annual Packaging Days | 330 Days | ||

| Work Shifts | 2 Shifts/16 Hours | ||

| Daily Average Packaging Capacity | ~40 KL | ||

| 330ml Glass Bottle Proportion | ~20 KL | ||

| 330ml Can Proportion | ~10 KL | ||

| 20L Stainless Steel Keg Proportion | ~10 KL | ||

| 1L Tinplate | 0 |

Bottling Line Capacity Planning:

| Total Capacity | Phase I | Phase II | |

| 330ml Bottle Proportion | ~20 kL/day | ||

| Work Shifts | 2 Shifts/16 Hour | ||

| Daily Bottling Quantity | ~60,000 Bottles/Hour | ||

| Daily Bottling Time: | 14 Hours | ||

| Bottling Line Capacity | ~5000 Bottles/ Hours |

Canning Line Capacity Planning

| Total Capacity | Phase I | Phase II | |

| 330ml Can Proportion | ~10KL | ||

| Work Shifts | 2 Shifts/16 Hour | ||

| Daily Canning Quantity | ~30,000 Cans/Day | ||

| Daily Canning Time | 14 Hours | ||

| Canning Line Capacity | ~2500 Can/Hour |

| Total Capacity | Phase I | Phase II | |

| 20L US Standard Keg Proportion | ~10KL | ||

| Work Shifts | 2 Shifts/16 Hour | ||

| Daily Kegging Quantity | 500 Kegs/Day | ||

| Daily Kegging Time | 14 Hours | ||

| Kegging Line Capacity | ~40 Kegs/Hour | ||

VI. Site and Facility Planning:

Land Use Planning:| Project | Suggest Areas |

| Production Land | >5000M2 |

| Warehouse Land | >3500M2 |

| Storage Yard | >1000M2 |

| Office Land | >500M2 |

| Road Land | >1000M2 |

| Parking Land | >200M2 |

| Green Land | >1000M2 |

| Utility Facilities Land | >500M2 |

| Total Land | >12000M2 |

Workshop Planning

| Project | Suggest Areas |

| Raw Material Storage Workshop | >300M2 |

| Crushing Workshop | >50M2 |

| Mashing Workshop | >300M2 |

| Fermentation Workshop | >1000M2 |

| Filtration Workshop | >200M2 |

| Packaging Workshop | >2000M2 |

| Utility Engineering Workshop | >600M2 |

| Total Area | >4500M2 |

Warehouse Planning

| Project | Suggest Areas |

| Packaging Material Warehouse | >1500M2 |

| Finished Product Warehouse | >2000M2 |

| Total Area | >3500M2 |

Building Planning

| Project | Suggest Areas |

| Office Building | >500M2 |

| Living Building | >300M2 |

| Facility Building | >200M2 |

| Total Area | >1000M2 |

VII. Supporting Facilities Planning:

| Supply Method | Equipment Requirements | |

| Water Supply Station | City water supply | |

| Substation | Factory substation | Transformer |

| Steam Supply Station | Industrial park steam supply or self-built boiler room | Steam Boiler |

| Energy Supply Station | Pipeline natural gas or LPG tanks | |

| Wastewater Treatment Station | Industrial park wastewater treatment station or self-built wastewater treatment station | Wastewater treatment equipment |

| Refrigeration Station | Self-built refrigeration station | Refrigeration equipment, etc. |

| Compressed Air Station | Self-built compressed air room | Air compressors, etc. |

VIII. System Introduction

Part 1: Raw Materials Preparation

1. Grist Storage System:

Main Grain Raw Materials for a Brewery:

The primary grain raw materials for a brewery include barley malt, wheat malt, and rice flour. The storage and supply of malt can be handled in two forms: flat storage and vertical silos. Flat storage is mainly suitable for bagged packaging and breweries with smaller storage capacities. Silos, compared to flat storage, are more suitable for bulk raw materials and offer larger storage capacities. Generally, breweries require malt and auxiliary material storage to meet 10-30 days of usage. The silo system not only meets storage needs but also enables automatic feeding, saving labor.

Capacity Design:

² Types of Malt: 3

² Malt Storage Duration: 15 days

² Malt Batch/Daily Usage: 2 tons/12 tons

² Malt Bulk Density Ratio: 1.3 m³/ton

² Total Silo Volume: ~234 m³

² Total Silo Volume Configuration: 300 m³

² Main Equipment Composition:

² 100 m³ Steel Silos: 3 units

² Bucket Elevators: 2 units

² Horizontal Scraper Conveyors: 2 units

² Operation Platform: 1 set

² Related Valves, Sensors, etc.

Performance Features:

Storage Capacity: Single silo design and manufacturing capacity of 100-1500 m³.

Good Material Flow: Excellent free flow, suitable for barley malt, wheat malt, etc.

Self-Unloading: Cone-bottom steel silos are erected on a supporting steel frame structure, allowing stored products to unload easily under gravity.

Easy Discharge: The corrugated wall panels of the assembled cone-bottom steel silos are smooth internally, with no steps or flanges, making it easy to discharge stored grains.

Automatic Retrieval: The cone-bottom steel silos are elevated above the ground to prevent moisture in stored materials. Adjacent silos are interconnected via conveying devices, enabling on-demand extraction of malt and other raw materials.

Configuration Features:

Material Structure: Cone-bottom galvanized corrugated panel assembled steel silos, consisting of three parts: silo roof, silo body, and cone bottom.

Cone-Bottom Silos: The ring stiffeners and supporting steel frame are made of hot-dip galvanized corrugated steel plates, which are lightweight yet sturdy.

Cone Bottom: Depending on the stored material, the cone angle is typically designed at 45º or 60º, suitable for storing materials with different flow properties.

Inlet/Outlet Configuration: Equipped with bucket elevators, which occupy a small footprint, enable vertical lifting, and have high lifting capacity, allowing for automatic vehicle unloading into the silos.

Roof and Bottom Configuration: Horizontal scraper conveyors are installed for feeding and discharging between different silos, enabling automatic control without manual intervention.

Supporting Features: A safety operation platform is provided on the silo roof for daily inspections and maintenance.

This system ensures efficient, automated, and labor-saving storage and handling of malt and other raw materials in a brewery.

2. Wet Malt Milling System:

Functions: malt preparation, crushes malt into grist while minimizing husk damage and oxidation, optimized for lautering efficiency.

Subcomponents

1. Destoner/Stone Removal Unit:

Technical Details: vibratory sieve+airflow separator to remove stones, metals, or debris from malt.

Benefits: protects downstream equipment and ensures purity of grist.

2. Malt Washer/Steeping Chamber:

Technical Details: pre-wets malt(6-8% moisture) to soften husks before milling.

Benefits: reduces dust, improves husk integrity for better lautering.

3. Wet Mill Rollers:

Technical Details: dual stainless steel rollers with adjustable gap settings(0.5-2.0mm)

Benefits: precise grind control for optimal starch exposure and husk preservation.

4. Dust Collection System:

Technical Details: cyclone separator+HEPA filters to capture fine particulates.

Benefits: maintains air quality and prevents explosive dust accumulation.

5. Magnetic Separator:

Technical Details: inline magnet traps ferrous contaminants post-milling.

Benefits: protects pumps and valves from metal debris.

6. Girst Hydration Unit:

Technical Details: spray nozzles evenly distribute water to conditioned grist.

Benefits: prepares grist for mashing-in with consistent moisture.

Part 2: Brewing System

Mashing System Introduction:

The mashing system is one of the most critical components in beer production equipment. Its design must align with mashing processes to ensure high-quality wort, which directly impacts fermentation, filtration efficiency, and the final flavor of the beer. The mashing process includes key stages such as gelatinization, saccharification, wort filtration, boiling, whirlpooling, and wort cooling.

The mashing system design must strictly control production parameters, including mashing temperature, mashing time, mash concentration, and pH levels. The wort filtration system aims to maximize the yield of clear wort, improve production efficiency, and separate soluble extracts from the mash while minimizing the inclusion of compounds that could negatively affect beer flavor.

During the boiling process, hops are added in batches. Modern boiling techniques ensure heating efficiency and energy savings while effectively removing undesirable compounds like DMS (dimethyl sulfide). After boiling, the wort is transferred to a whirlpool tank to separate hot trub and hop residues, resulting in clear wort. The wort is then cooled to fermentation temperature using a plate heat exchanger and oxygenated to support yeast growth and reproduction.

Key Equipment in the Mashing System:

v Gelatinization kettle

v Mashing kettle

v Lauter tun or filter press

v Boiling kettle

v Whirlpool tank

v Plate heat exchanger

v Venturi oxygenation system

v Yeast addition system

Designed with modern brewing technology and tailored to the diverse needs of craft beer production, the mashing system ensures precise process control, improved production efficiency, and optimized resource and energy savings.

Part 3: Fermentation System

Introduction to the Fermentation System:

Fermentation is an extremely crucial process in beer production, involving complex biochemical reactions with the participation of yeast. Fermentation is typically carried out in indoor or outdoor cylindrical-conical fermentation tanks. These tanks are equipped with an automatic cooling system, allowing for easy control of the fermentation temperature. The conical bottom of the tank facilitates the recovery of yeast. The tanks are also fitted with a CIP (Cleaning-in-Place) system, enabling comprehensive, no-dead-angle cleaning and sterilization, ensuring the hygiene and safety of the production process. Depending on factors such as the fermentation cycle of different types of beer, the production ratio of various beer types, and the number of brewing batches, fermentation tanks of different specifications and quantities are configured.

Process Design Features:

v Fermentation Process.

v Closed pressurized fermentation.

v CIP Cleaning Process.

v Fully automated cleaning.

Dry Hopping Process:

Online hop addition using a hop gun.

Cooling Performance:

The entire system uses a 33% glycol mixture at -5°C as the cooling medium, providing gentle and efficient cooling.

Cooling rate: 0.8-1°C/hour from 18°C to 5°C, and 0.05-0.2°C/hour from 5°C to 0°C. Cooling parameters can be set to control the cooling speed at different stages.

Fermentation tanks feature multi-stage cooling at the lower cone and straight wall, enabling segmented temperature control. During primary fermentation, staggered cooling between the upper and lower sections ensures sufficient convective heat exchange. During storage, cooling intensity at the bottom can be reduced to prevent ice formation on the inner surface.

Automation Control Features:

Automation Level: The system is partially automated, with an automation level of approximately 50%.

Process Valve and Piping Operation: A piping corridor system controls various process flows, allowing centralized operation and saving labor.

Temperature Control: Cooling curve parameters can be set according to the recipe, and the system can automatically control the process based on the set parameters.

Level Control: Equipped with sanitary level sensors to monitor the fermentation liquid level in real-time.

Recipe Storage: Fermentation parameters for different beer types can be set and stored, forming a recipe management form. Pre-set recipes can be selected for automatic operation during brewing.

Alarm and Protection Automation: Different levels of fault alarms can be set, such as temperature anomaly alarms, valve open/close alarms, empty material level alarms, and liquid level alarms.

Safety Protection Automation: Maximum safety protection functions can be set, such as power-off when the manhole is opened and empty material stop protection.

Log Archiving: Operation logs of all electrical components are archived, enabling tracking and recording of brewing operations.

Hygienic Design:

The inner surface of the fermentation tank has a cleanliness level below 0.4 microns, meeting high standards for sanitary material use.

High-efficiency 360° rotating spray balls from renowned brands ensure full coverage with no dead angles.

Precise calculation of CIP cleaning parameters and high-quality cleaning pumps ensure strong flushing intensity.

Sanitary-grade pipelines from well-known brands are used, offering high cleanliness and easy cleaning.

All pipeline tees are welded with short-radius connections, eliminating cleaning dead angles.

Configuration Features:

Material: High-quality 304 stainless steel plates from Taiyuan Iron and Steel are used, offering acid resistance, corrosion resistance, and reliability under long-term high-temperature conditions.

Cleaning System: Equipped with an automatic CIP cleaning system and high-quality rotating spray balls, ensuring no dead angles inside the tank and maintaining hygiene during brewing.

Pipelines: Sanitary-grade pipelines from the renowned domestic brand Liyang Sifang are used, with high polishing precision and no sanitary dead angles.

Valves: High-quality stainless steel butterfly valves, angle seat valves, and diaphragm valves with imported valve cores are used, offering resistance to acid, alkali, high and low temperatures, and high sanitary standards.

Welding: Fully automated laser welding with 100% argon gas protection ensures uniform welding, minimal carbonization, low oxidation, and no ferrite precipitation. Welds are smooth, with high fusion, no bubbles, and no sand holes, meeting high sanitary standards.

Polishing: All welds undergo multi-level mechanical polishing and acid passivation treatment, with an inner surface roughness below 0.4 microns, meeting high sanitary material requirements.

Pumps: Sanitary-grade centrifugal pumps from the renowned domestic brand Liyang Sifang are used, ensuring stable operation and cleanliness.

Insulation: Polyurethane insulation with a foam density of 40± kg/m³ provides excellent insulation performance.

Safety: High-quality pressure relief valves with a pressure setting below 2 bar protect the tank from damage.

Maintenance: A platform on the tank top facilitates easy maintenance and inspection.

Part 4: Yeast Propagation System

Introduction to the Yeast Propagation System:

The yeast propagation system expands the pure yeast strains preserved by the brewery through a series of cultivation steps to achieve the required yeast quantity for production use. This system enables breweries to independently produce yeast, ensuring higher yeast purity and consistent yeast quality, thereby stabilizing beer quality. Yeast propagation begins with laboratory cultivation and separation, followed by cultivation in Carlsberg flasks, Hansen flasks, and expansion tanks, before being transferred to yeast storage tanks for eventual use in beer fermentation tanks. The yeast propagation system is suitable for breweries with large production volumes, professional teams, and experimental equipment.

Main Equipment Components:

v Carlsberg flasks: 2 units

v Primary expansion tank: 1 unit

v Secondary expansion tank: 1 unit

v Yeast storage tanks: 2 units

v CIP alkali tank: 1 unit

v Additionally includes pumps, valves, pipeline systems, and various supporting sensors.

Hygienic Design:

The inner surface of the yeast tanks has a cleanliness level below 0.2 microns, minimizing the risk of contamination.

Sanitary-grade pipelines from renowned brands such as Sifang are used, offering high cleanliness and easy cleaning.

All pipelines can undergo comprehensive CIP cleaning and steam sterilization to ensure sterility.

A steam heating device provides fully enclosed, dead-angle-free sterilization of wort, achieving truly sterile wort.

The air ventilation system uses sterile filters with steam sterilization to ensure sterile wort aeration.

High-efficiency 360° rotating spray balls from renowned brands ensure full coverage with no dead angles.

Configuration Features:

Material: High-quality 304 stainless steel plates from Taiyuan Iron and Steel are used, offering acid resistance, corrosion resistance, and reliability under long-term high-temperature conditions.

Cleaning System: Equipped with an automatic CIP cleaning system and high-quality rotating spray balls, ensuring no dead angles inside the tanks and maintaining hygiene during the process.

Pipelines: Sanitary-grade pipelines from the renowned domestic brand Liyang Sifang are used, with high polishing precision and no sanitary dead angles.

Valves: High-quality stainless steel butterfly valves, angle seat valves, and T-type valves with high sanitary standards are used.

Welding: Fully automated laser welding with 100% argon gas protection ensures uniform welding, minimal carbonization, low oxidation, and no ferrite precipitation. Welds are smooth, with high fusion, no bubbles, and no sand holes, meeting high sanitary standards.

Polishing: All welds undergo multi-level mechanical polishing and acid passivation treatment, with an inner surface roughness below 0.4 microns, meeting high sanitary material requirements.

Pumps: Sanitary-grade centrifugal pumps from the renowned domestic brand Liyang Sifang are used, ensuring stable operation and cleanliness.

Part 5: Centrifuge Filtration System

Introduction to Disc Centrifuge System

In the beer industry, disc centrifuges are primarily used to significantly remove yeast from beer, enhancing its clarity and reducing yeast sedimentation. This is particularly suitable for the brewing of wheat beer. Centrifugation technology extends the shelf life of beer to some extent while ensuring its freshness. It is commonly applied to fresh beer in cold chain distribution and can also be used in conjunction with flash pasteurization to further prolong the beer's shelf life. High-quality centrifuges must control oxygen ingress to below 5-10 ppb.

Main Equipment Components:

v Disc centrifuge: 1 unit

v Buffer tank: 1 unit (depending on process design)

v Includes corresponding pumps, pipelines, valves, sensors, etc.

Process Parameters:

Material parameters for separation: Beer fermentation liquid contains approximately 20-30 million yeast cells per milliliter.

Yeast content after separation: About 0.5-2 million cells per milliliter (adjustable online based on beer type, taste requirements, and visual appearance).

Oxygen control: Sealed water and CO₂ are used to avoid oxygen; post-separation oxygen increase is controlled between 5-10 ppb.

Sealed water: Deoxygenated water is used with a pressure of 0.25-0.4 MPa (adjustable), stable flow rate of 300-500 L/h. If deoxygenated water is unavailable, soft water with a total hardness (as CaO) <250 mg/L and meeting other drinking water standards can be used.

Cleaning solution and hot water: Pressure of 0.1-0.2 MPa, flow rate of 500-1000 L/h. If hot water is used for cleaning, it must meet drinking water quality standards.

Cooling water: Pressure of 0.1-0.2 MPa, flow rate of 1-2 m³/h, temperature ≤ process material temperature -4°C, meeting tap water quality standards.

Compressed air: Pressure of 0.5-0.7 MPa. The air must be clean, dry, free of significant corrosive impurities, with solid particles <0.1 g/m³, particle diameter <3 µm, oil content <5 mg/m³, and a dew point >3°C.

Carbon dioxide: Pressure of 0.15-0.3 MPa, purity ≥99%, moisture ≤50 ppm, usage rate of 6-7 NM³/h.

Equipment Features:

Automatic slag discharge: Includes partial and full slag discharge.

Sealed labyrinth design: Ensures minimal oxygen ingress during centrifugation. The self-designed centripetal pump system offers stable output pressure, wide adjustment range, and easy operation.

Frequency conversion drive: Ensures smooth operation with no noise or odor pollution.

Fully automatic control cabinet: Equipped with safety protection devices, allowing direct adjustment of separation parameters (separation and slag discharge times) on the display for optimal results.

Vibration monitoring: Equipped with a fully automatic vibration detector to monitor vibration intensity, with automatic alarm and shutdown functions if standards are exceeded.

Speed monitoring: Equipped with a speed detector to monitor actual speed, ensuring separation effectiveness and allowing intuitive adjustments based on product requirements.

Small cyclone slag discharge device: Effectively reduces noise during slag discharge.

Cooling jackets on upper and lower covers: Controls temperature rise in beer (varies with coolant), ensuring beer quality, reducing noise, and improving the operating environment.

Emergency stop switch: Located at easily accessible positions for immediate shutdown in emergencies, ensuring operator and equipment safety. The device will only resume operation after manual restart following fault resolution and power restoration.

Integrated base frame: Fully enclosed design, made of stainless steel 304, with all pipelines, equipment, and control systems centralized. The device can be flexibly installed based on site conditions, preventing material leakage and maintaining a clean, aesthetically pleasing appearance.

CO₂ gas sealing interface: Prevents oxygen dissolution during beer separation, preserving beer quality.

Oxygen control: Post-separation oxygen increase is controlled between 5-10 ppb.

Part 6: Diatomite Filtration System

Introduction to Candle Diatomite Filtration System

The candle diatomite filtration system is one of the most commonly used filtration methods in the beer industry. The system primarily consists of a candle filter, complemented by a series of auxiliary equipment such as front and rear buffer tanks, a diatomite mixing and dosing tank, a beer head and tail tank, and corresponding pipelines, valves, and sensors. The candle diatomite filter is mainly composed of numerous vertical filter candles. The filtration aid (diatomite) is pre-coated and then attached to the outer surface of the filter candles through secondary and tertiary pre-coating. The filtration aid is continuously added via the mixing and dosing system. After pre-coating, it effectively filters out yeast, cold break solids, and other impurities from the beer, resulting in a clearer product.

Main Equipment Components:

v Silica gel dosing tank: 1 unit

v Front buffer tank: 1 unit

v Diatomite mixing and dosing tank: 1 unit

v Candle filter: 1 unit

v Rear buffer tank: 1 unit

v Bag-type catcher: 1 unit

v Additional dosing systems as per process requirements

v Includes related pumps, valves, pipelines, sensors, and operating platforms.

Part 7: Brite System

The brite system is designed to receive filtered or otherwise processed beer liquid, serving as a storage tank before filling, where it undergoes carbonation prior to packaging. It can also be used as a storage system for beer after fermentation. The main components include sake tanks of various specifications and the corresponding pipeline systems. The specifications and quantity of the sake tanks are determined based on the capacity of the fermentation tanks and the filling system. Factors such as the types of beer being filled and the proportion of different beer varieties are fully considered in the configuration.

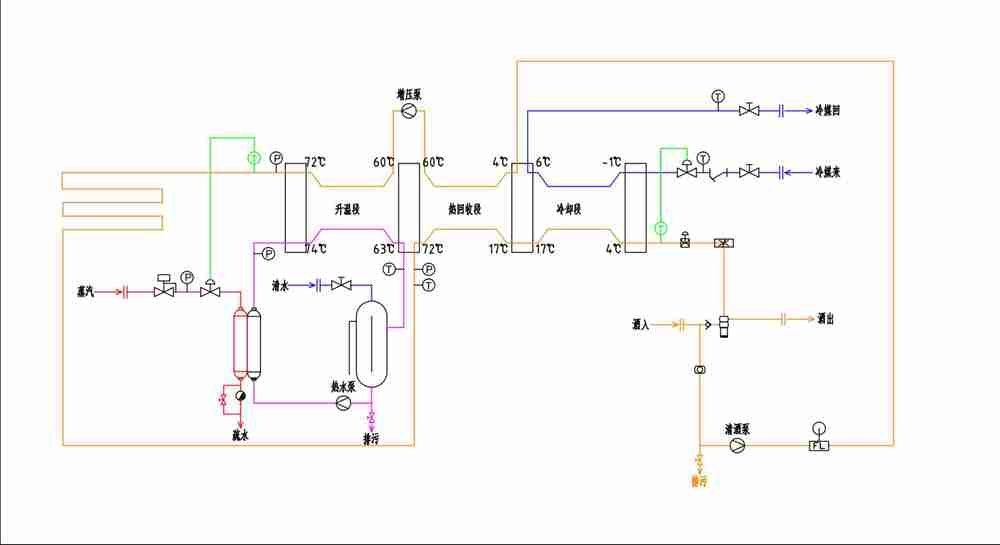

Part 8: Flash Pasteurization System

Introduction to Flash Pasteurization System for Beer

Flash pasteurization is applied just before the filling process, where high-temperature steam is used to heat the beer for a short duration of 35-40 seconds to achieve sterilization. After heating, the beer is rapidly cooled to preserve its flavor to the greatest extent and minimize the development of aged tastes. Following flash pasteurization, strict aseptic filling is often employed. This method is commonly used in the production of fresh beer.

Main Equipment Components:

v Flash pasteurizer: 1 unit

v Buffer tank: 1 unit

v Additionally includes pumps, valves, piping systems, various sensors, and a tank-top operation platform.

Configuration Features:

Customizable according to the process requirements for heating, sterilizing, heat retention, and cooling of the material.

Utilizes a German JOMO PID temperature controller with an accuracy of ±0.1°C.

Employs internationally renowned brands for valve sensors, such as Spirax Sarco for steam valve assemblies, Grundfos for material pumps, and ifm or E+H for electromagnetic flow meters, ensuring stable performance and precise control.

Equipped with a CIP (Clean-In-Place) cleaning system to ensure hygienic and safe production.

Part 9: High-Concentration Dilution System

Introduction to High-Concentration Dilution System:

In the diverse beer market, light and refreshing beers have always been favored by consumers. High-concentration dilution technology is one of the significant innovations in producing such beers. It is crucial to ensure the beer's flavor and body stability while avoiding issues like bland taste, coarse foam, poor foam retention, reduced mouthfeel, decreased color intensity, poor body balance, and non-biological instability. These requirements impose higher standards on the design and manufacturing of high-concentration dilution equipment. Tiantai Company's specially designed mixing structure and carbon dioxide cutter allow the beer liquid to fully interact with carbon dioxide molecules, continuously transitioning from laminar flow to radial and turbulent flow states. This enhances the dissolution of components such as alcohol, water, and carbon dioxide additives in the beer liquid. The pipeline mixer, under the action of a pressure-holding line, increases the mouthfeel of the beer during large-scale dilution, ensuring that the diluted beer meets the required standards. The system is equipped with a precise carbon dioxide metering system, which successfully controls the carbon dioxide content in the final diluted product, addressing the issue of carbon dioxide instability.

Part 10: Controlling System

Introduction to Control Systems

The automation system in a brewery is one of the most critical components in the modern beer production process. It includes the automation control system, monitoring system, and data analysis system.

The automation control system can replace traditional manual operations, improve brewing consistency, and reduce labor costs. It enables precise control over parameters such as temperature, time, liquid level, pressure, stirring speed, pump speed, conductivity, pH value, and wort concentration, ensuring the stability of beer quality in a more scientific and effective manner. Based on different beer brewing recipes and process requirements, pre-set programs allow each brewing unit to operate in a coordinated and efficient manner, reducing reliance on personnel and effectively avoiding human errors. This significantly enhances production efficiency and reduces brewing losses.

The automation monitoring system is used to monitor various parameters in real-time during the production process, including temperature, pressure, and flow rate. By installing sensors at key points, real-time production data can be collected, analyzed, and evaluated. If any abnormalities are detected, the system will immediately issue an alarm and initiate corresponding measures for adjustment.

The data analysis system is a crucial component for summarizing and analyzing production data. By statistically analyzing and modeling large amounts of historical data, it identifies issues and areas for improvement in the production process. Additionally, using technologies such as machine learning and artificial intelligence, models can be established to predict potential abnormalities during production, enabling early warnings and automatic adjustments.

Main Equipment Components

v MCC control cabinet: 1-2 units

v PLC control cabinet: 1-2 units

v Sub-control cabinets: 3-10 units

v Computer workstations: 1-2 sets

v Operating system: 1 set

v Brewing program: 1 set

v Other components include power cables, communication modules and cables, and installation cable trays.

Part 11: CIP System

Part 12: Concentrated Acid and Alkali Dosing System

The concentrated acid and alkali dosing system is designed to add acid, alkali, and disinfectants to the CIP (Cleaning-in-Place) system. Since concentrated acids and alkalis are hazardous chemicals, manual dosing poses certain safety risks. The dosing system enables unmanned, automatic dosing, with the entire process being carried out through enclosed pipelines, thereby avoiding safety hazards to personnel.

Main quipment Components

v Concentrated alkali tank (liquid alkali): 1 unit

v Concentrated acid tank: 1 unit

v Disinfectant tank: 1 unit

v Other components include pumps, pipelines, valves, sensors, etc.

Part 12: Water Treatment System

Introduction to Cold Process Tower Deoxygenated Water Supply System

The cold process tower deoxygenation system uses carbon dioxide (CO2) to replace oxygen in water, achieving the deoxygenation effect.

Main Equipment Components:

v Deoxygenation Tower: 1 unit

v Plate Heat Exchanger: 1 unit

v CO2 Static Mixer: 1 unit

v Deoxygenated Water Storage Tank: 1 unit

v Related Pumps, Valves, Pipelines, and Detection Sensors.

Part 12: Cooling System

Part 12: Steam Supply System

Introduction to Steam Supply System

In breweries, steam is widely used for heating and sterilization purposes, such as wort mashing, wort boiling, yeast propagation, flash pasteurization, pasteurization, and pipeline sterilization. Steam offers advantages such as high thermal efficiency, gentle heat transfer that minimizes the risk of damaging materials, and low heat loss during transportation. The fuel for steam boilers can be selected based on local conditions, including natural gas, LPG, electricity, diesel, biomass, and others.

Main Equipment Components:

v Steam Boilers: 1-2 units

v Steam Distribution Headers: Several

v Condensate Tank: 1 unit

v Energy Storage Tank: 1 unit (configured based on size requirements)

v Related Steam Pipelines, Valves, etc.

Part 13: Compressed Air Supply System

Introduction to Compressed Air Supply System:

In breweries, compressed air is primarily used to power various pneumatic components, the spent grain removal system, and other applications. For these uses, the compressed air only requires basic filtration to remove water and oil. After thorough purification, compressed air is also utilized in processes such as wort oxygenation and CO2 replacement in fermentation tanks.

Main Equipment Components:

v Oil-free Air Compressors: 2 units

v Air Buffer Tank: 1 unit

v Air Refrigerated Dryer: 1 unit

v Filters: Several

v Related Pipelines, Valves, etc.

Configuration Features:

Oil-free Compression: Utilizes oil-free air compressors to prevent oil contamination in the air.

Air Buffer and Impurity Removal: Equipped with a buffer tank where compressed air enters, allowing impurities to settle and separating most water, oil, and dust. These impurities are then discharged from the system through a drain port.

Air Filtration: The number of filters and their placement in the compressed air system vary based on the required air quality. A basic setup includes filters with precision levels of 3μm, 1μm, and 0.01μm. Additional specialized filters such as "oil removal filters," "bacterial filters," and "activated carbon filters" are configured according to process requirements.

Compressed Air Drying: Includes a dryer, typically a refrigerated type, to remove moisture that condenses due to temperature changes during the use of compressed air, ensuring the air meets the requirements of its application site.

Part 14: CO2 Supply&Collect System

Introduction to Carbon Dioxide Recovery System

Carbon dioxide (CO2) is a crucial raw material in the beer production process. During beer fermentation, a significant amount of CO2 is generated, while a large quantity of CO2 is also required as a raw material in beer production. The recovery and utilization of CO2 can effectively save energy and reduce production costs.

CO2 gas from the beer fermentation tank first passes through a defoamer to remove foam carried by the gas. It then enters a washing tower to eliminate most of the suspended particles and organic impurities, achieving initial purification. The gas subsequently enters an airbag, and the CO2 compressor automatically adjusts its load based on the liquid level in the airbag, compressing the gas to 1.7-1.85 MPa. Next, the gas enters a pre-cooler to remove most of the moisture. After passing through an activated carbon adsorber to further eliminate residual organic impurities and odors, it is dried in a molecular sieve dryer to remove any remaining moisture, ensuring the CO2 gas reaches a dew point temperature below -45°C at atmospheric pressure. The purified CO2 gas then enters a liquefier for heat exchange. The refrigeration capacity of the liquefier is provided by two screw refrigeration compressors, which automatically adjust their load based on the pressure in the CO2 storage tank. After heat exchange, the liquefied CO2 (approximately 1.8 MPa, -18°C) flows by gravity into the CO2 storage tank. The liquefied CO2 is then vaporized in a vaporizer, and the purified gas, meeting food hygiene standards, is distributed through pipelines to various departments for use.

Main Equipment Components:

v Defoaming Tank: 1-4 units

v Washing Tower: 1 unit

v Airbag: 1 set

v Compressor: 1 unit

v Deodorizing Dryer: 1 unit

v CO2 Liquefier: 1 unit

v Refrigeration Unit: 1 set

v Liquid CO2 Storage Tank: 1 unit

Part 15: Filling System

Introduction to Glass Bottle Filling System

This system is designed for filling glass bottles with carbonated beverages such as soda, beer, and iced tea, and sealing them with crown caps. Equipped with a secondary vacuum system and using CO2 as the back pressure in the beverage tank, the machine effectively reduces the intake of oxygen (O2) in the bottled beer. Moreover, the CO2 content not only remains stable but can also increase. This makes the machine particularly suitable for filling high-quality beers with a longer shelf life.

Main Equipment Components:

v Depalletizer

v Bottle Washer

v Bottle Filler

v Capping Machine

v Tunnel Pasteurizer

v Bottle Dryer

v Labeling Machine

v Coding Machine

v Conveyor

v Bottle Arranger

v Shrink Wrapping Machine

v Case Sealer

Performance Features:

High filling accuracy, controllable within ±2ml

CO2 replacement in empty cans, isobaric filling, adjustable filling parameters online, and one-key product quality switching

Modular design for simple and efficient installation and debugging

Centralized discharge of overall cleaning table, with all material contact parts made of stainless steel for hygiene

Star wheel transfer in the filling and sealing area replaces the traditional can lifting table, ensuring stable operation and saving space

Optional imported sealing wheels to enhance service life

Compact size and low output, suitable for craft and personalized products

Equipped with CIP cleaning cups for automatic CIP cleaning

Part 16: Project Delivery

Production

Production Cycle

Transportation

Installation

Installation Cycle

Commissioning

Training

Part VII: Project Settlement

Part VIII: On-site Construction

Part IX: After-sales Service

Warranty

Maintenance

Servicing

Personnel Training

Feel free to contact us for more interested information:

E: [email protected]

Sharon

Tiantai Company

.jpg)

.jpg)

.jpg)

Get A Quote