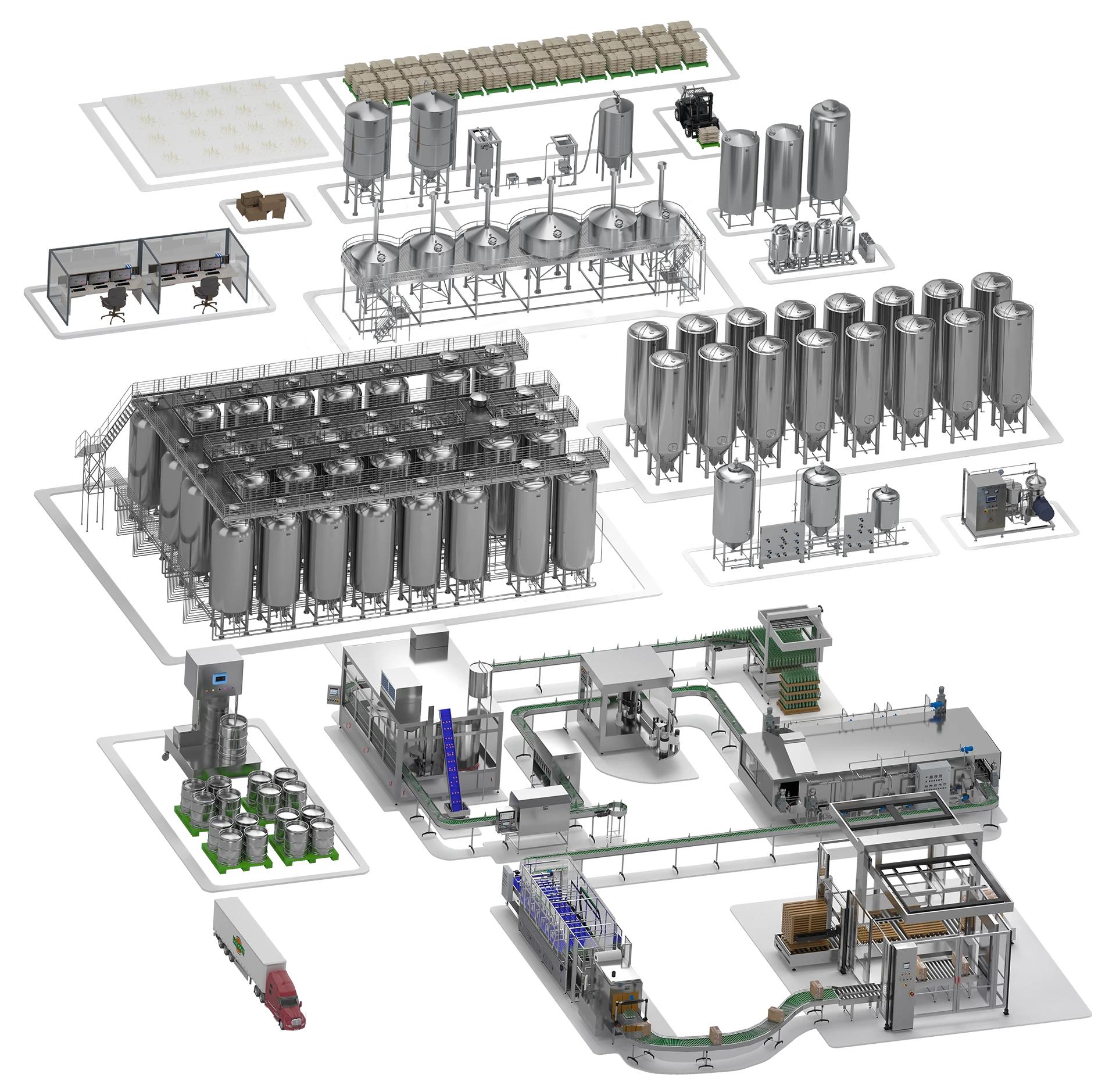

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment, provides comlete lines and the turnkey service for breweries and beverage projects worldwide. At Tiantai, we have spent over 12 years helping brewers worldwide turn their passion into profit. As a trusted name in beer and beverage equipment, we know what it takes to build a brewery that is efficient, reliable, and ready to grow. Today we are happy to introduce the 250HL Industrial Brewery System, a state-of-the-art, fully integrated brewing solution designed for breweries seeking efficiency, precision, and scalability. Engineered with cutting-edge technology and industry-leading expertise, this system ensures seamless production from raw material handling to finished product packaging.

| Output/Brew | 250HL |

| Brew/day | 5-10 |

| Output/Day | 125kl to 250kl beer per day based on different configuration |

| Output/Year | 3.75Wkl-7.5Wkl |

| Electric Supply | 3phase/380(220, 415,440…)v/50 (60)Hz |

| Heating Source | Steam heating |

| Area Request | >6000㎡ |

| Brewmaster | 12-18 |

| Mashing method | Decoction,infusion,multi-step infusion |

1. Malt Storage Silo

High-capacity malt storage silo ensures optimal preservation of raw materials with advanced humidity and temperature control.Built for durability and hygiene, it guarantees consistent malt quality while minimizing contamination risks.

2. Wet Milling System

The wet milling system delivers precise grain crushing, enhancing starch exposure for improved mashing efficiency.Closed-loop design--reduces dust and waste, ensuring a cleaner, safer workspace.

3. Mashing System

Based on brewing needs, 4 vessel, 5 vessel, 6 vessel available.Main features:

Precision Temperature Control

Fully automated, multi-zone heating ensures exact temperature gradients for optimal enzyme activity, maximizing starch-to-sugar conversion and wort quality.

High Efficiency & Speed

Rapid heating and cooling cycles reduce mashing time by up to 20%, boosting daily output without compromising consistency.

Stainless Steel Durability

Crafted from food-grade 304/316L stainless steel, resistant to corrosion and wear, ensuring longevity even under heavy use.

Energy-Saving Design

Integrated heat recovery modules reuse excess thermal energy from the boiling phase, cutting energy costs by 15-30%.

Easy Maintenance

Smooth surfaces, wide-access doors, and CIP compatibility eliminate dead zones and simplify cleaning.

Scalable Automation

PLC-driven controls allow recipe programming, real-time adjustments, and seamless integration with other brewery systems.

Consistent Results

Uniform mixing and temperature distribution guarantee repeatable mash profiles for every batch, ideal for diverse beer styles.

4. Fermentation Tanks

Robust outdoor fermentation tanks are designed for temperature and pressure stability, even in harsh environments.Equipped with cooling jackets and monitoring sensors, they ensure consistent yeast performance and flavor development.

5. Yeast Propagation System

Optimize yeast health and vitality with our scalable propagation system.Its sterile environment and automated nutrient dosing enable rapid yeast expansion, reducing lag time between batches.

6. Filtration System

Achieve crystal-clear beer with a dual-stage filtration system combining centrifuges and diatomaceous earth filters.Modular designs allow customization for different beer styles and clarity requirements.

7. Sterilization Systems

Flash pasteurization (for minimal flavor impact) and tunnel pasteurization (for extended shelf life) optional.8. High-Gravity Dilution System

Increase production flexibility and reduce costs with our high-gravity brewing module.Precise dilution controls enable adjustment of alcohol content and flavor profiles post-fermentation.

9. Centralized Control System

The fully automated PLC control system offers real-time monitoring and adjustments via an intuitive interface.Remote access capabilities ensure 24/7 oversight of the entire production line.

.jpg)

10. CIP (Clean-in-Place) System

Streamline sanitation with automated CIP modules that reduce downtime and water consumption.Programmable cycles target equipment-specific cleaning needs for unmatched hygiene.

11. Packaging & Filling Systems

Versatile filling options include bottles, kegs, cans, and bright beer tanks.High-speed fillers minimize oxidation, while integrated labeling and packaging units ensure ready-to-ship products.

.jpg)

12. CO2 Recovery System

Capture and reuse CO2 generated during fermentation, reducing environmental impact and operational costs.Our system meets stringent purity standards for carbonation and inert gas applications.

.jpg)

13. Cooling System

Energy-efficient chillers maintain precise temperatures across fermentation, storage, and dispensing stages.Variable-speed compressors adapt to fluctuating demands, cutting energy costs by up to 30%.

14. Steam Heating System

Rapid, uniform heating for brewhouse operations is achieved through steam boilers with advanced safety controls.Ideal for mashing, boiling, and CIP processes.

15. Compressed Air System

Reliable oil-free compressors deliver contaminant-free air for pneumatic controls, packaging, and other critical applications. Energy recovery modules further enhance sustainability..jpg)

16. Water Treatment System

Customizable water purification units adjust pH, hardness, and mineral content to match brewing requirements. Reverse osmosis and UV sterilization ensure water quality meets global standards.Why Choose Tiantai’s 250HL Brewery System?

End-to-End Integration: Seamless coordination of all components for maximum efficiency.Sustainability Focus: Energy-saving designs and CO2/water recycling reduce environmental footprint.

Scalability: Modular architecture supports future expansion.

Global Compliance: Meets ISO, CE, and ASME certifications.

Elevate your brewing operations with Tiantai’s innovation solutions. Contact us to customize your industrial brewery system proposal!

Contact: Cassie

Email: [email protected]

.jpg)

.jpg)

.jpg)

Get A Quote