An Ideal Entry-Level Solution for Craft Bottling Projects

This semi-automatic to fully automatic bottling line is tailored for small-batch beverage production. It’s widely used in the packaging of craft beer, kombucha, cold brew coffee, soda, and juice. With a compact layout and food-grade stainless steel structure, it helps producers upgrade from manual to professional bottling without overwhelming investment.

Key Features:

✔ Compact footprint, easy to operate✔ Modular design, easy to expand or upgrade

✔ Compatible with various bottle sizes (200–500ml)

✔ Designed for clean-in-place (CIP) and hygienic production

✔ Optional modules to suit different production goals

System Overview

1. Empty Bottle Platform

Feeds bottles into the filling line automatically.Made of food-grade 304 stainless steel, it ensures stable feeding of bottles to the rinsing-filling-capping unit.

2. 3-in-1 Beer Filler (Rinse / Fill / Cap)

Core machine of the line – integrates 3 functions:Rinsing: 8 heads ensure internal bottle cleaning

Filling: 6 heads gravity or low-pressure filling

Capping: 1 head for crown caps or twist-off caps

✅ Applicable for 330ml standard bottles (customizable)

✅ Adjustable speed: 200–500 bottles/hour

3. Automatic Cap Loader (Optional)

Feeds caps into the capping station automatically.Reduces manual labor and keeps production continuous and efficient. Suitable for crown caps, aluminum twist caps, etc.

4. Bottle Drying Machine (Optional)

Removes surface moisture from bottles before labeling or packaging.Equipped with high-speed blowers and stainless steel casing, it enhances label adhesion and packaging quality.

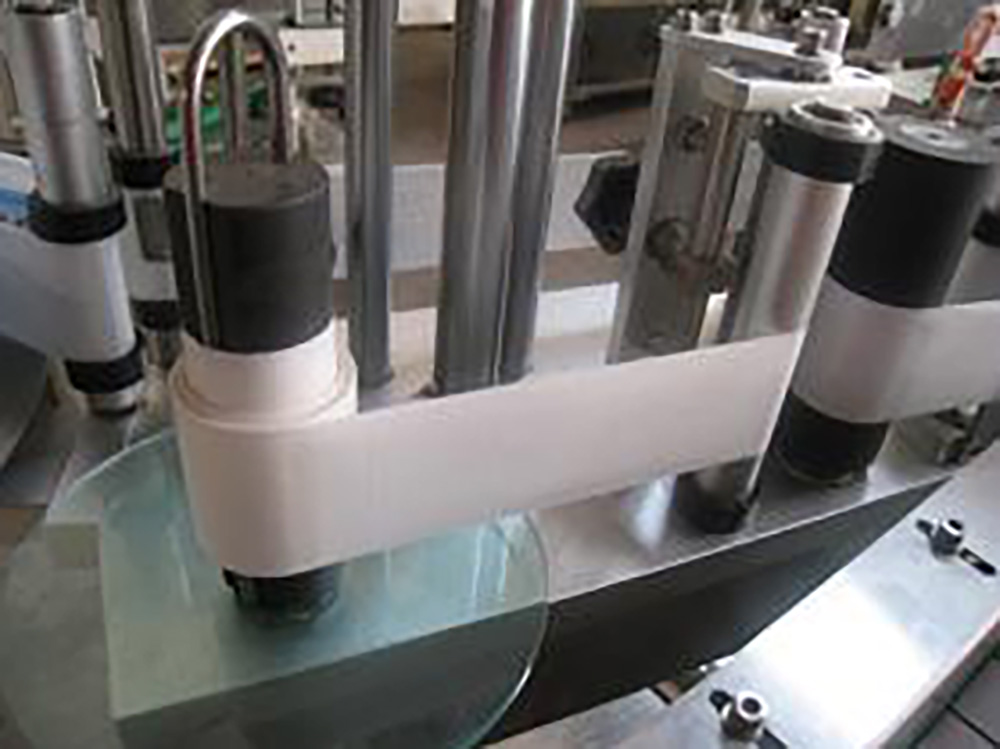

5. Labeling Machine

Applies single-side self-adhesive labels to each bottle.Speed: 500–3000 bottles/hour

Accuracy: ±1mm

Adaptable for bottles 30–90mm in diameter

6. Inkjet Date Printer (Optional)

Prints production date, lot number, and expiry info on bottle neck or label.Supports high-speed and multi-line printing. Variable font size and layout.

7. Bottle Collection Platform

Receives and collects finished bottles at the end of the line.Large-diameter stainless steel turntable ensures smooth bottle output and packaging prep.

Simplified Technical Summary

| Item | Specification |

| Filling Capacity | 200–500 bottles/hour |

| Bottle Size | 200–500ml (customized) |

| Power Supply | 380V, 3-phase (customizable) |

| Material | Food-grade SS304 for all contact parts |

| Optional Add-ons | Cap loader, dryer, printer, dual-label system |

| Application Range | Beer, Kombucha, Cold Brew, Juice, Soda |

Application

Start-up beverage brandsSmall breweries or coffee roasters

Test or pilot bottling projects

Seasonal or specialty drink production

Ready to upgrade from manual bottling?

Tiantai’s 200–500BPH line gives you a clean, compact, and cost-effective packaging solution.

Contact us today for a detailed quotation and layout proposal customized to your needs.

Edited by Cassie

Email: [email protected]

.jpg)

Get A Quote