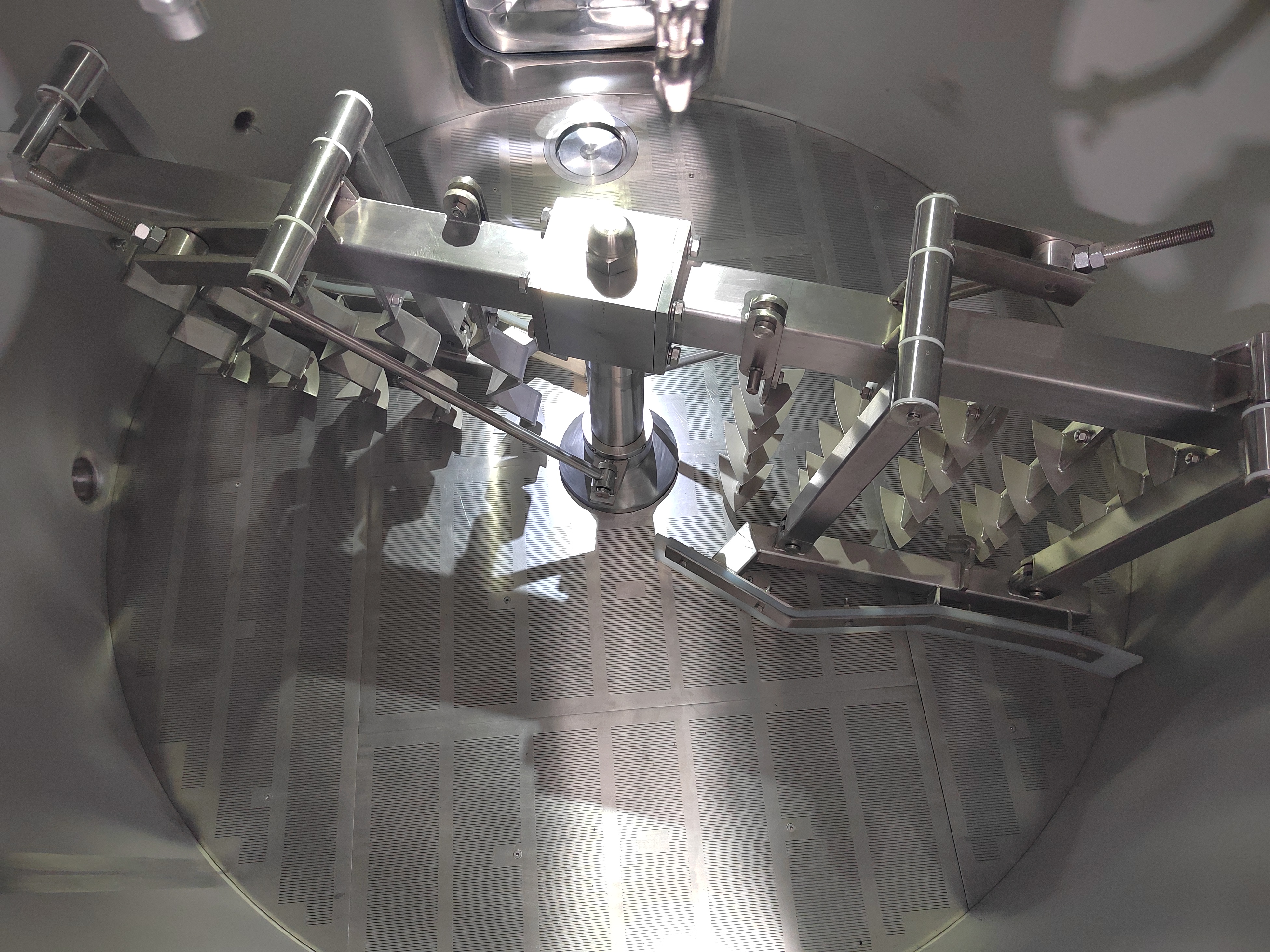

In brewery equipment, the lauter tun is an essential vessel used in the lautering process, which is a key step in beer brewing. The false bottom is a critical component of the lauter tun, and its function is as follows:

The false bottom is a perforated or slotted plate or screen that is placed at the bottom of the lauter tun. Its primary function is to act as a filter to separate the solid grain material (spent grain) from the liquid wort during lautering. The lautering process involves rinsing the mashed grains with hot water to extract the fermentable sugars and other soluble components from the grain bed.

Here's how the false bottom works in the lauter tun:

Grain Bed Support: The false bottom provides support to the grain bed, preventing it from compacting or clogging the drainage system. It ensures that there is enough space for the liquid wort to flow freely while keeping the grain particles in place.

Filtration: As the hot water is sprayed or circulated over the grain bed, it interacts with the crushed malt, dissolving the sugars and other soluble compounds. The liquid wort, containing these extracted components, filters through the false bottom's openings, leaving the solid grain particles above.

Wort Collection: Once the liquid wort has passed through the false bottom, it is collected in the space beneath the false bottom, known as the wort collection chamber. From there, it can be drained out of the lauter tun and further processed in the brewing process.

Spent Grain Separation: The false bottom prevents the solid spent grain from being carried into the wort collection chamber. Instead, it acts as a barrier, ensuring that only the liquid wort can pass through.

By using a false bottom in the lauter tun, brewers can efficiently separate the wort from the spent grain, allowing them to collect the sugary liquid needed for fermentation while leaving the solid grain material behind. This is a crucial step in the beer brewing process, as it sets the stage for the next phases of brewing, such as boiling and fermentation.

TIANTAI company provides 5-150HL fermentation tanks, and also provides a complete set of turnkey brewery projects. If you are planning to build a brewery or expand the brewery, we warmly welcome your proposal and we are happy to provide you with support.

Edited by Cassie

E-mail:[email protected]

Get A Quote